AIRLAB Singapore: Architectural Intelligence Research Lab

Singapore

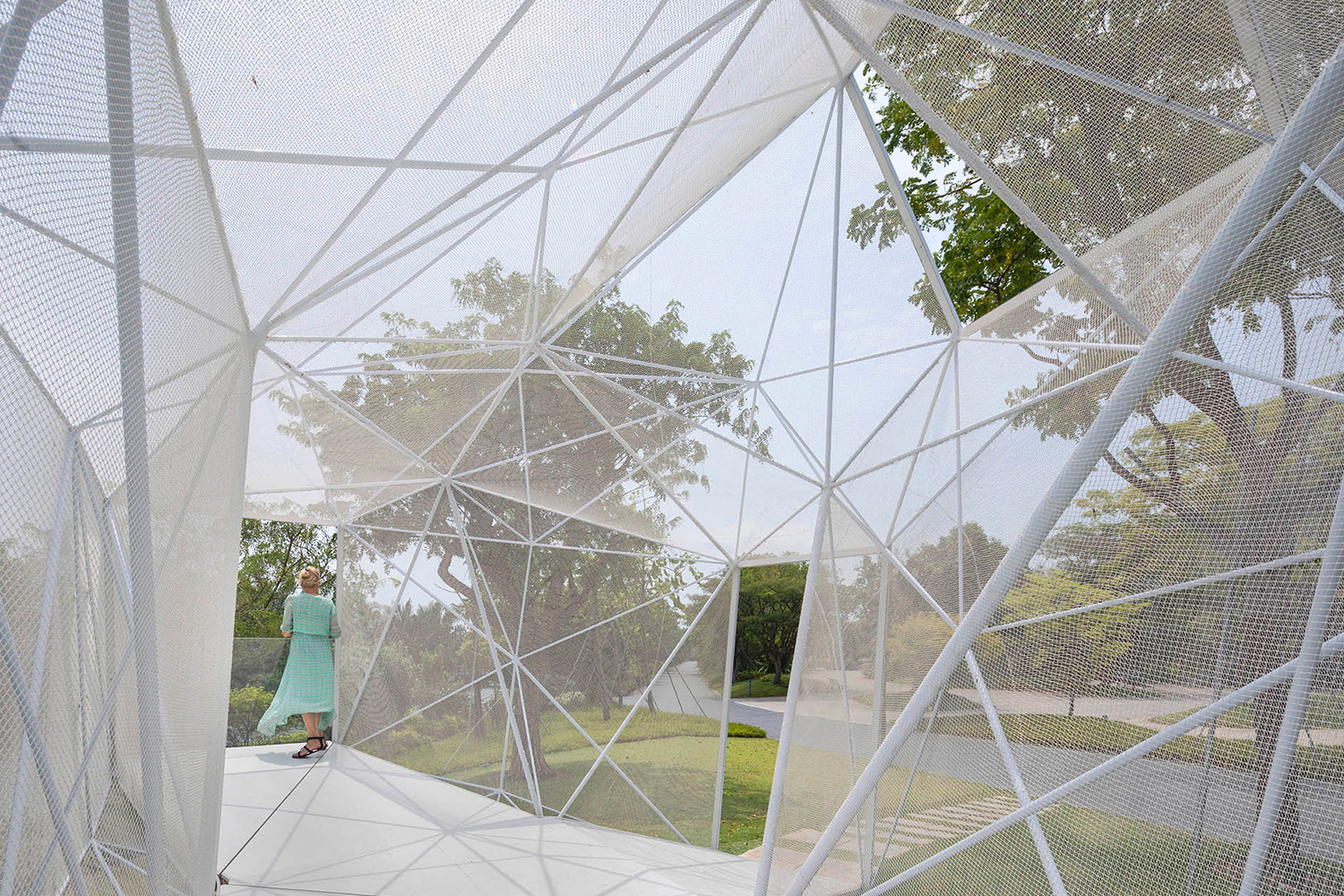

AIRLAB (Architectural Intelligence Research Lab) is a multidisciplinary research laboratory that works in the intersection between architecture, arts and digital design and manufacturing. AIRLAB uses advanced manufacturing technologies (AM) to work with raw materials like steel, concrete and plastics for architectural constructions. It explores the use of new technologies as part of seamless workflows from ideation to fabrication. Its Singapore Director is Carlos Banon. Its Chile Director is Felix Raspall.

AIRLAB’s ambition is to achieve more efficient, adaptable, versatile and lighter products by introducing new technologies like 3D printing and digital manufacturing. AIRLAB targets zero-wastage in construction, by using additive manufacturing in functional components. AIRLAB explores new, meaningful ways to utilise the 3D-printed systems to increase sustainability and efficiency (to shorten development and assembly time) and introduce new typologies with the potential for adoption.

The lab is capable of developing an entire workflow to make a design happen. AIRLAB codes its own algorithms for the design and fabrication of its ideas. Most components are printed in a precise and fine manner, allowing tolerances of less than a millimetre – a feat that is more common in aerospace and rarely seen in the architectural industry. This minimises errors in construction as the design and fabrication processes are completely digital and almost fully automated. For the assembly stage, a clear step-by-step sequence is automatically generated by AIRLAB’s software, which requires no specific training to execute, and which creates a positive experience.

Using 3D printing in construction is still a rare practice in the world. AIRLAB has acquired deep expertise over the last five years and gained traction internationally. Starting locally with partners like JTC, HDB and Keppel Land, the lab’s Directors believe that they can soon go out and pitch new projects regionally or globally using 3D printing. AIRLAB will also continue to push the envelope as 3D printing costs drop steadily in the future, which can then generate even more mainstream traction.

Photography: Carlos Banon, Fabian Ong